Heat Transfer Printing and How it WorksUpdated 15 days ago

Image Credit: epson.com

Printing Categories used for Quadra Products

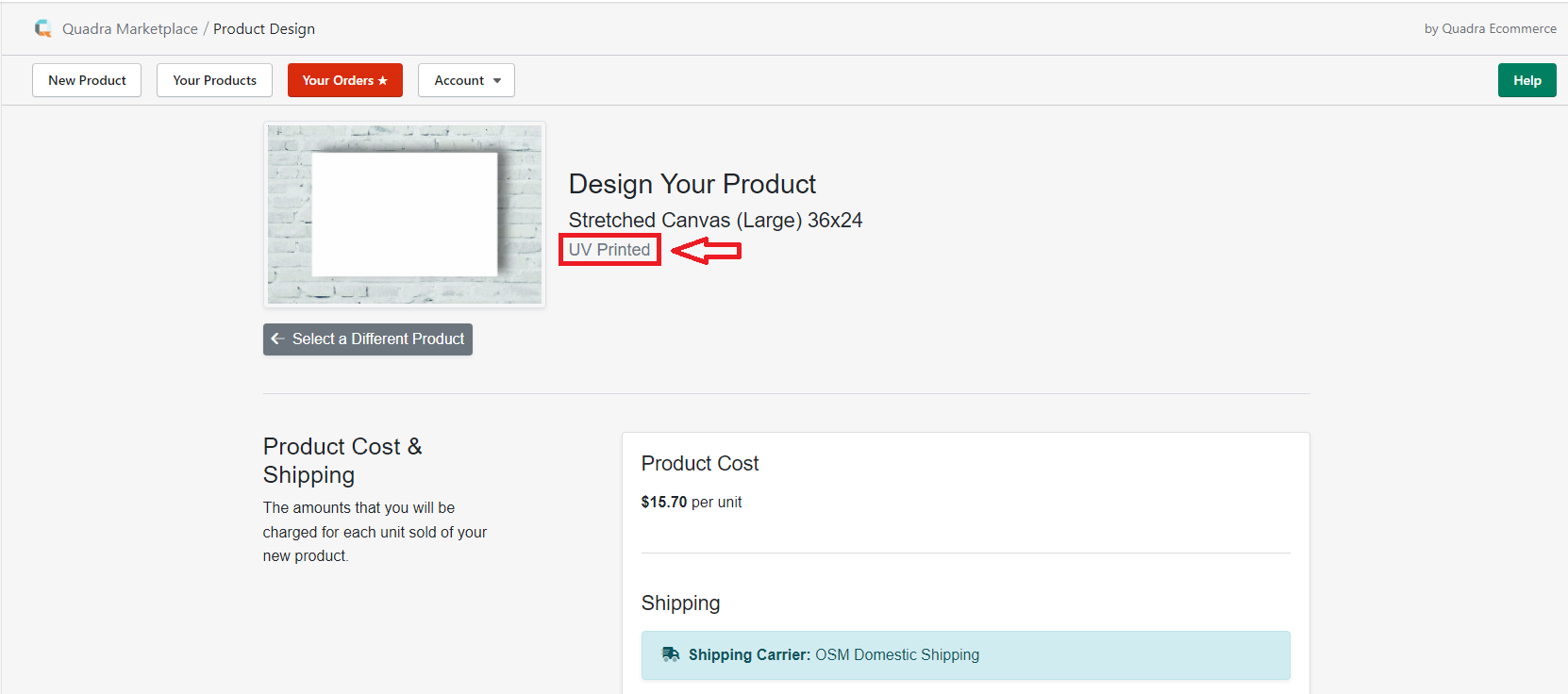

All the Products in the Quadra App's catalog have different styles of printing. If you would like to see what type of printing will be used on the product you would like to launch, first select the product from the product catalog. Selecting the product will bring you to the product details page. Located under the product name is the print type. Image A-2 shows an example.

All the printing is done automatically for you and there is no way to change print styles on each product, but if you would like to know more about the way your products will be printed we invite you to read our articles regarding the different printing processes. This article will cover heat transfer printing.

A-2

A-2

What is Heat Transfer Printing?

Heat transfer printing is a printing process where a heating press is used to transfer a design from a heat transfer paper to a material, most commonly fabric. The process for heat transfer printing is most similar to dye sublimation printing, the key difference being what happens when the design is transferred to the garment. For heat transfer printing, the transferred design adheres to the fabric as a very thin layer on top of the garment. This differs from dye sublimation because dye sublimation ink is designed to change into a gas when exposed to heat. In it's gaseous form the dye sublimation ink infuses into the fabric so there is no layer on top.

The difference between the two processes is most noticeable in the textures. When you use heat transfer printing, because it ads the design as a layer on top of the clothing you can feel the design on top of the garment, whereas with dye sublimation there is no noticeable texture.

Image Credit: blog.printsome.com

Image Credit: blog.printsome.com

How does Heat Transfer Printing Work?

The first thing you want to do when heat transfer printing is to print off your design. You can use a normal inkjet printer for this. You do need to make sure that you use the special heat transfer paper for the process to work properly. There are a few different kinds of heat transfer paper. The specific instructions regarding heat temperature, time under the heat press, and when to remove the paper from the design, are all specific to what heat transfer paper is used.

After the design is printed on the heat transfer paper it is time to move to the heat press. It is a good idea to put the garment under the heat press for a few seconds before applying the design. Heating the garment before applying the design ensures that any moisture in the garment evaporates so it won't interfere with the process.

After the garment has been preheated it is time to apply the design. Be sure to put the design the right way down to make sure the design adheres to the garment and not the heat press. After ensuring that the design is in the exact location you want it in, place a protection sheet between the garment and the heating press. This step is not required for every material but is a good practice as some materials are heat sensitive.

There are specific timing instructions for how long to hold the garment under the heating press for each heat transfer paper but typically the garment is only held under the heat press for around thirteen seconds. Once this is done, lift the heat press and remove the protection paper. Next it is time to remove the heat transfer paper. Once again, specific instructions regarding whether to remove the heat transfer paper when the garment is hot, warm, or cold, will be specific to the heat transfer paper being used. If the process went correctly then the heat transfer paper should come up, leaving the design behind.

Image Credit: ipromo.com

What Materials does Heat Transfer Printing Work on?

One of the main benefits of using heat transfer printing is the versatility it offers. As far as materials go, heat transfer printing can print on all fabrics. Because heat transfer printing applies a thin layer on top of the garment, it can easily be applied to any color of fabric, including black. Dye sublimation, on the other hand, fails in this area, as it is limited to only light colored fabrics that are made out of polyester. While it is rare to use heat transfer printing on materials other than fabric, it is possible to do so on a few hard materials, such as ceramic.

Limitations of Heat Transfer Printing

If texture is of concern on the garment you want to print your design on to then heat transfer printing isn't the right process for your needs. Dye sublimation or one of the other garment printing processes can offer a good alternative to heat transfer printing.

Additionally, if long lasting durability is important to you, heat transfer printing may not be right for your product. Due to the design being applied to the garment as a layer on top of the garment, it is more likely for the design to crack and/or peal with use. This being said, heat transfer printing still provides a durable print that can last up to 20-30 washes before it starts to crack, depending on the size of the design and the way it is washed.

Image Credit: iconique.co

If you would like to see heat transfer printing in action check out these videos!

Video Credit: SanMar Videos

Video Credit: MD Textile

Haven’t created your Shopify store yet? Click Here to get your store set up now!

Not yet a Quadra Pro subscriber? We have a FREE masterclass that will teach you Print On Demand basics and a special offer included at the end. Click Here to sign up today!

Interested in a database of POD ready designs? We recommend using Creative Fabrica for thousands of designs, images, and fonts. All come with a sales license. Click Here to check them out!