Direct to Garment (DTG) and How it WorksUpdated 16 days ago

Image Credit: aprilsales.com

Printing Categories used for Quadra Products

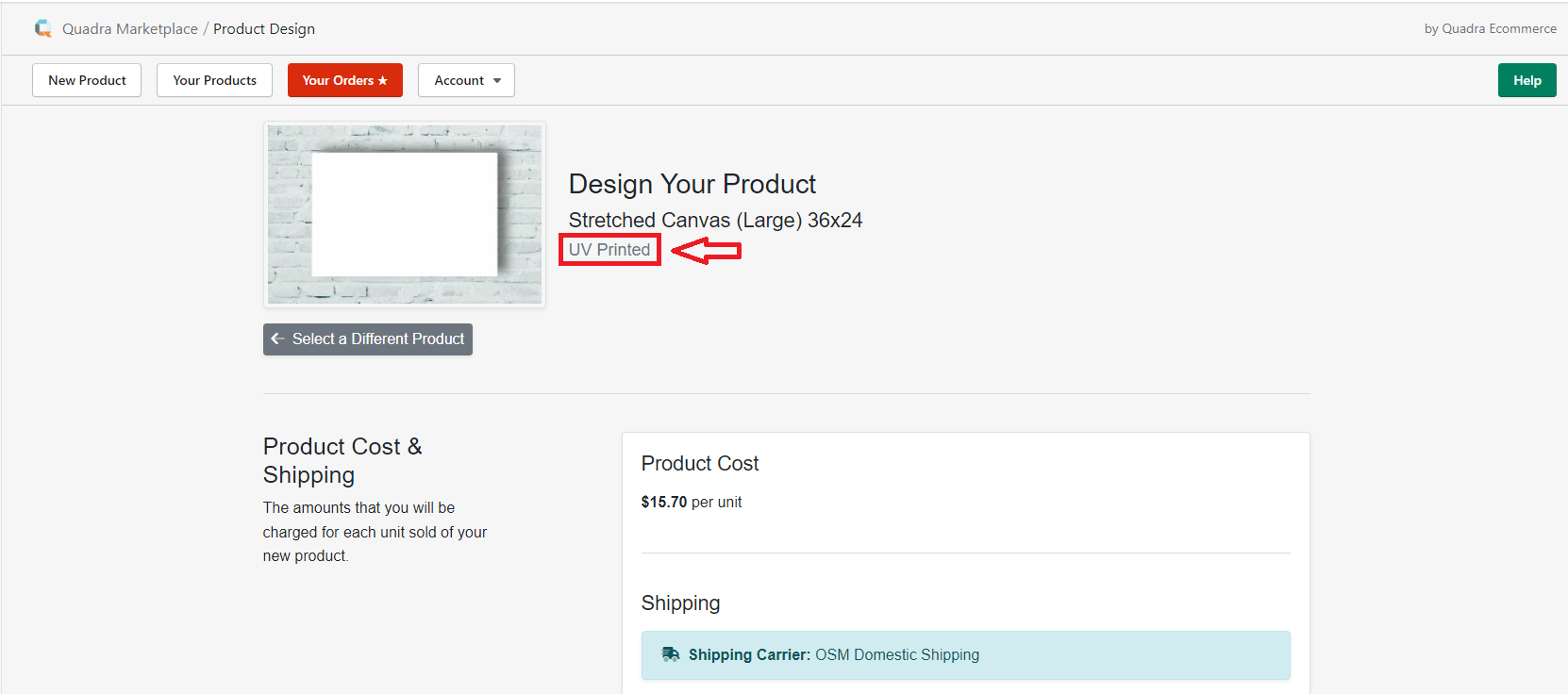

All the Products in the Quadra App's catalog have different styles of printing. If you would like to see what type of printing will be used on the product you would like to launch, first select the product from the product catalog. Selecting the product will bring you to the product details page. Located under the product name is the print type. Image A-2 shows an example.

All the printing is done automatically for you and there is no way to change print styles on each product, but if you would like to know more about the way your products will be printed we invite you to read our articles regarding the different printing processes. This article will cover direct to garment printing.

A-2

A-2

What is Direct to Garment Printing?

Direct to garment printing, commonly referred to as DTG printing, is the process of digitally printing a design directly onto any fabric garment, most commonly a t-shirt. The process is much like printing onto a piece of paper except that a specific printer is required to make the process work. Direct to garment printing is a durable and detailed way of printing a design onto a garment, the downside is that it takes significantly longer to print the images than the alternative, screen printing. DTG is best used for products that are going to be sold only a few at a time, such as with print on demand selling.

Image Credit: midwestworld.com

Image Credit: midwestworld.com

How does Direct to Garment Printing work?

Before a shirt can be printed on, it needs to go through a pre-treatment process where a pre-treatment liquid is sprayed on the fabric. From here it is important to take a paint brush and brush the fabric, this step ensures that the pre-treatment liquid is spread evenly across the entire surface of the fabric. The pre-treatment solution is what prepares the fabric to be printed on. Without the pre-treatment the ink won't adhere to the fabric as easily and the design won't turn out right.

The pre-treatment also ensures that the design is safe for machine washing. A DTG printed garment shouldn't fade/smear in the washing machine. If it does, that's a sign that something went wrong with the pre-treatment.

After the pre-treatment has been sprayed and brushed, the next step before printing is to put the garment in a heat press. The heat press dries the shirt and prepares the pre-treatment solution for printing. After the heat press, the shirt is ready to be placed in the printer. It's important to get the shirt lined up exactly where you want it so the design is printed in the right area of the shirt as well as being centered properly.

After the printing is completed, the next step is to put the shirt back into the heat press. This is done to help cure the ink so it is safe for washing. After this step the shirt is finished and ready for sale.

What Material Works Best with Direct to Garment Printing?

For direct to garment printing it is recommended that the garments are made out of 100% cotton as the ink adheres to cotton best. It is possible to use cotton polyester blends but doesn't work as well as the 100% cotton option.

If you would like to see direct to garment printing in action watch this video!

Image Credit: Coastal Business Supplies

Haven’t created your Shopify store yet? Click Here to get your store set up now!

Not yet a Quadra Pro subscriber? We have a FREE masterclass that will teach you Print On Demand basics and a special offer included at the end. Click Here to sign up today!

Interested in a database of POD ready designs? We recommend using Creative Fabrica for thousands of designs, images, and fonts. All come with a sales license. Click Here to check them out!